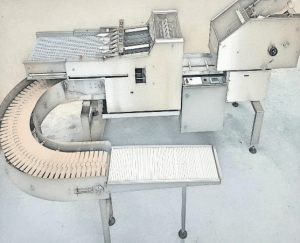

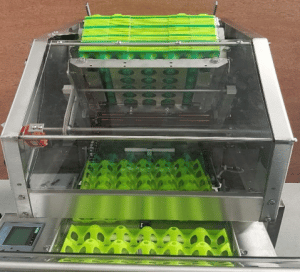

SRJ Davidson Farm Packing System

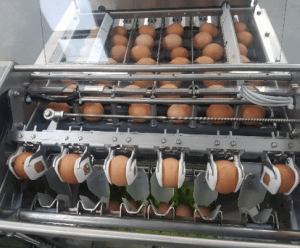

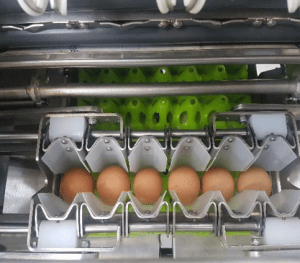

The Davison range of Farmpackers have been developed over many years in close conjunction with egg producers in UK and Ireland. They are engineered for very gentle egg handling with a simple compact design that has low labour requirement.

Key features:

- Compact layout only 2.2m long for 5 row packer with left or right hand version available.

- Layout with reverse flow packing lane and takeaway conveyor located at operator

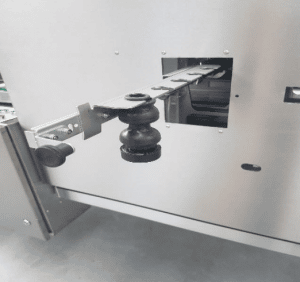

position for convenient stacking and quality control. - Positive orientation with turn bars and grippers gives very gently egg handling and high

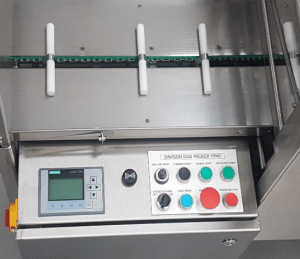

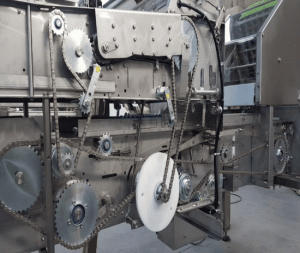

% points down on all egg sizes. - Only 1 variable speed drive motor controls all packer functions through clutches.

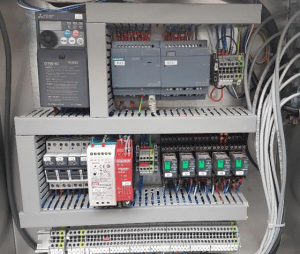

Operation is by simple stop/start buttons. No vacuum or pneumatics. PLC display screen

shows egg counter and status indication. - Integrated stamping at low cost, easily accessible on linear slide.

- All stainless steel construction with nickel plated chains for washdown capability.

Maintenance free chains optional. - Traystacker options available with up to 20 stack takeaway for further labour saving.

- Handles all known paper and plastic trays with minor adjustments.

Technical Data:

- FP40 – 13,000 eggs/hour

- FP70 – 22,000 eggs/hour

- FP100 – 36,000 eggs/hour

- Electrical – 1 drive motor 0.18kw

- variable speed

- Supply – 240 Volt Single Phase

Labour Requirements:

- FP40 – 1 Operator

- FP70 – 2 Operators or 1 Operator with Traystacker

Optional Extras:

- Nuovo Egg Stamping

- Nuovo Egg Printing

- Various Modifications to Infeed and Takeaway